Table of Contents

Report

EscarGO® - The Escargot Nursery

Authors:

- Lauri Borghuis

- Benjamin Calon

- John MacLean

- Juliette Portefaix

- Ramon Quero

Acknowledgement

Team one “Caracol” would like to thank European Project Semester (EPS) and Instituto Superior de Engenharia do Porto (ISEP) for the chance to participate in this project, which was a once in a lifetime opportunity for us to grow and develop ourselves both professionally and personally.

The Team would also like to thank the panel of supervisors for the support, help and advice they gave the Team on a weekly meeting basis, as well as the teachers that offered some very helpful pieces of advice during the semester.

Glossary

| Abbreviation | Description |

|---|---|

| B2B | Business to Business |

| B2C | Business to Consumer |

| CD | Compact Disc |

| CNISF | Conseil National des Ingénieurs de France |

| COD | Cash On Delivery |

| EPS | European Project Semester |

| EU | European Union |

| FAQ | Frequently Asked Questions |

| IOT | Internet Of Things |

| ISEP | Instituto Superior de Engenharia do Porto |

| LCD | Liquid Crystal Display |

| LED | Light-Emitting Diode |

| PESTLE | Political / Environmental / Social / Technological / Legal / Economic |

| PETA | People for the Ethical Treatment of Animals |

| PMMA | Polymethylmethacrylate |

| PP | Polypropylene |

| PVC | Polyvinyl Chloride |

| RAM | Responsibility Assignment Matrix |

| ROHS | Restriction Of Hazardous Substances |

| RTC | Real Time Clock |

| SEO | Search Engine Optimization |

| SMART | Specific / Measurable / Attainable / Relevant / Time Based |

| SWOT | Strengths / Weaknesses / Opportunities / Threats |

| USB | Universal Serial Bus |

| WBS | Work Breakdown Structure |

| 3D | Three-Dimensional |

1. Introduction

1.1 Presentation

The Team was undertaking the EPS Project in Portugal, studying at ISEP in Porto. The Team named “Caracol”, which means snail in Portuguese, consisted of five students all from different countries, cultures, speaking different languages, and above all with differing knowledge bases. This diversity, which could have been an obstacle, was instead the driving force that enabled the Team to make this project unique, creative and innovative.

The Team was composed of:

- Lauri Borghuis, from The Netherlands, studying Biology and Medical Laboratory Research

- Benjamin Calon, from Belgium, studying Product Development

- John MacLean, from Scotland, studying Mechanical Electronic Systems Engineering

- Juliette Portefaix, from France, studying General Engineering

- Ramon Quero, from Spain, studying Engineering and Architecture.

Team “Caracol” (see Figure 1) was a multidisciplinary, hardworking group of people who wanted to improve and develop communication and Team working skills as well as other soft skills, while learning about marketing, ethics and project management. Because of the multidisciplinary aspect of EPS, each team member learned something new from a field of study that they had not experienced before.

Each member had a personal motivation to enrol on the EPS program:

Lauri Borghuis: “EPS seemed to me to be an excellent opportunity to make new social contacts with international students. I chose EPS to work in a group with international students with all different fields of study, so I could learn from their fields, and I could share my knowledge. Furthermore, studying for six months abroad was good for my development in the English language”.

Benjamin Calon: “The EPS program trained us in a different way than normal school courses. It gave us soft skills to work with students from different backgrounds (professional and cultural). Going out of my comfort zone, improving my language skills and enjoying the local culture were the ingredients for an extraordinary experience”.

John Maclean: “EPS gave me a chance to live abroad for a few months and experience a different culture. It allowed me to meet people from all over Europe and make friends and connections for life. It put me far out of my comfort zone and also gave me a chance to develop another language”.

Juliette Portefaix: “EPS was for me a great opportunity to discover a new way of working. It was a chance to discover a new culture and new people. EPS also enabled me to develop my management skills, and to learn how to work in a Team. Finally, it was the best way to improve my English”.

Ramon Quero: “I saw EPS as a nice chance to improve my teamwork skills by working in a project with colleagues from different nations and backgrounds, an opportunity to speak in a foreign language and to learn other skills like communication, marketing or project management. It was also an unforgettable life experience”

1.2 Motivation

The project that has been chosen was an “Escargot Nursery”. This option was chosen for several reasons.

First of all, this was the subject which allowed the mix of each of the differing specialties thus allowing each member to bring their own experience and skill set from the various specialties.

Another reason for making this decision was that the Team believed it was the most original and unusual project. None of the team members had any prior knowledge of snails before the start of the project which provided its own challenge, but also allowed the whole Team to learn something completely new. It enabled the Team to satisfy their curiosity, and be more open minded to new disciplines. The Team believed that this product fulfils a genuine desire with families who wanted to learn more about food, and be more sustainable in food production.

In France, there were not enough snails being produced for the amount of snails being consumed, so the French import a large amount of snails every year. The Team wanted to create a new way of producing food that would be fun for kids, that would include technology and that would provide a comfortable habitat for the snails. If the end user did not want to use the enclosure for producing food then they could also use it to keep the snails as pets. The Team decided that education would be a main objective for the product, and that would be one of the main selling points. The enclosure would be able to house fifty snails, which would take six months to reach full maturity.

1.3 Problem

More people are aware of the use of genetically modified organisms and, consequently, want to know the origins and growth process of their food. Genetic modification is used to improve the colour, smell and taste of food, trying to make it more attractive and durable in terms of the shelf life. However, the problem is that there is not enough scientific knowledge regarding the long-term side effects of genetically modified food on people [1].

The digital revolution had improved our communication channels through the likes of social media, mobile phones, and video conferencing, but it had also isolated people becoming addicted to their smart phones and not living real social life. Social media came with its pitfalls also, with people trying to project the perfect life, and comparing themselves to others. Depression and mental health issues had become more common among young people [2].

The Team saw this reality and decided they wanted to create something that would help towards a happier healthier lifestyle. They realised more people are opting for organic food, and wanted to know where their food came from. Also, many more people wanted to grow their own food at home and wanted to reduce their carbon footprint. This product fitted into this brief well.

One of the problems that came with this project was that the snails had to be kept within the cage with no chance of escape. One of the issues was the laws in a particular country might not allow the production or domestic use of snails as they were believed to be pests or non-native species, which could severely harm the ecosystem, such as the Giant African Snail [3].

1.4 Objectives

The goal was to design and build a unique and innovative product that would help people to produce their own snails at home, whether for recreational purposes or consumption. The main objective was to bring families together and educate children about animals and food. Additionally, the product provided two meals a year for a family of four as the Cornu aspersum grew, one of the most commonly consumed breed of snails, to the optimal size in six months [4].

This product should be sustainable and protecting the environment around us since this was becoming more important due to the impact of climate change. The Team tried to reduce their environmental impact, by creating a low impact system and using low impact materials. The design needed to be simple but attractive.

The “EscarGO” must provide a way to produce food at home, as this allowed for a reduction in food travel, since food could travel from all over the world before it ended up in the supermarket. This reduced the carbon footprint of the food that reached the dinner table. It also provided a project which families could do together to bond.

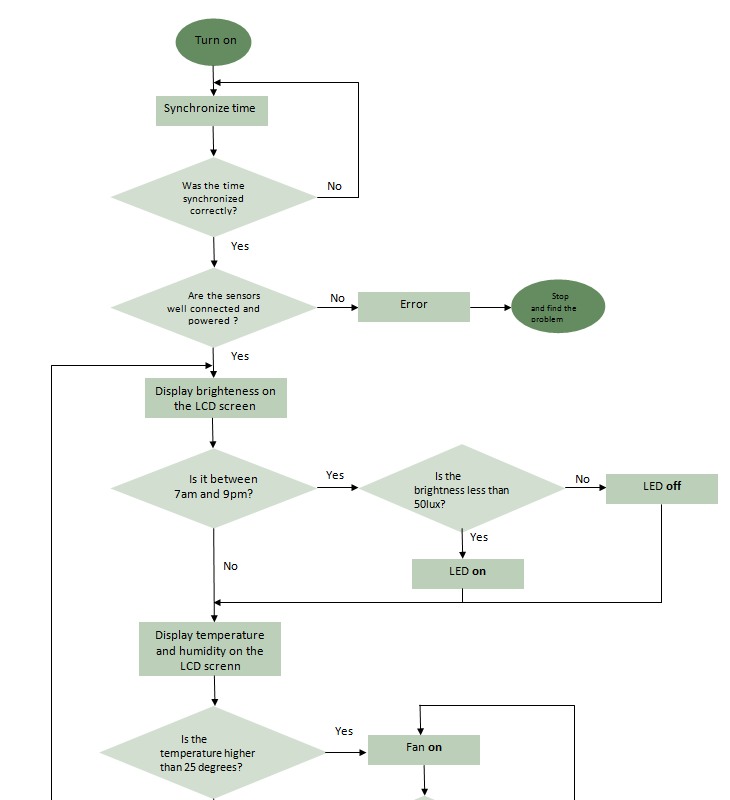

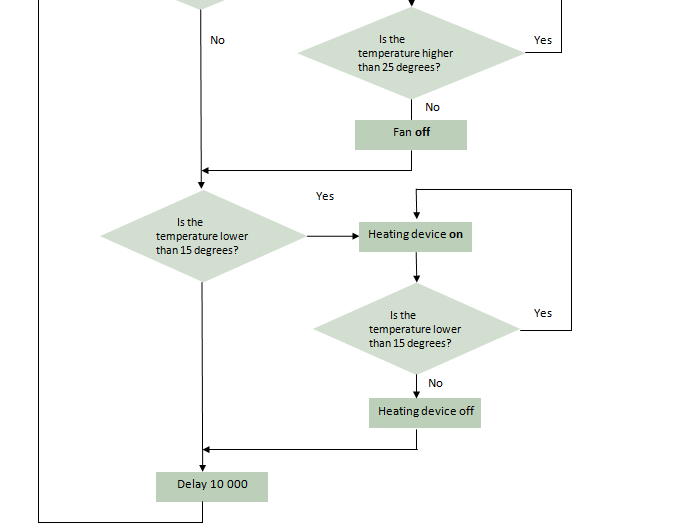

The product should provide a means for people to grow snails in an easy way. Temperature and humidity monitoring were very important, so the sensors needed to transmit all the relevant information to the controller, and allowed full automation, with little human interaction.

1.5 Requirements

The Escargot Nursery had to meet several requirements. It had to:

- Have an attractive aesthetically pleasing design

- Set, display and control the internal temperature, light and humidity

Some other project requirements were:

- Use sustainable materials

- Use low cost hardware solutions

- Stick to the budget (100.00 €)

- Comply with the following European Union (EU) Directives:

- Machine Directive (2006/42/CE 2006-05-17);

- Electromagnetic Compatibility Directive (2004/108/EC 2004 12 15);

- Low Voltage Directive (2014/35/EU 2016-04-20);

- Radio Equipment Directive (2014/53/EU 2014-04-16);

- Restriction of Hazardous Substances (ROHS) in Electrical and Electronic Equipment Directive (2002/95/EC 2003-01-27);

- Mandatory adoption and use of the International System of Units (The NIST International Guide for the use of the International System of Units)

- Use open source software and technologies.

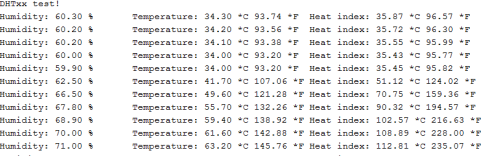

1.6 Functional Tests

To evaluate the work, the Team had to perform certain functional tests. These tests gave an insight into whether the Escargot Nursery was ready to be released to the market.

- Temperature + Humidity Sensor: Test the correct operation of both sensors by using ice to lower the temperature and using a hair dryer to raise the temperature.

- Light Sensor: Test the light sensor by covering the sensor to see if the lights switch on automatically.

- Cooling Fan: Test the cooling fan operation by increasing the temperature above 25 °C, with the help of the hair dryer.

- Electric Heater: Test if the heater activates when the temperature decreases below 15 °C, by placing an ice cooling pack inside “EscarGO”.

- Liquid Crystal Display (LCD): Test if the LCD displays the temperature, light level and relative humidity.

- Water Tank: Test if the water tank works to moist the soil, and check that there are no water leakages.

1.7 Project Planning

Every project needed to be planned carefully because a project plan gives an overview of all the tasks and deliverables that need to be completed. Having a good project plan and following it well allowed the smooth running of the project, and kept the project running on schedule. Table 1 shows the planning used for this project. In Chapter 3.3 there is a comprehensive project plan including a Gantt chart.

| Task | Responsible |

|---|---|

| Project Plan | |

| Task Allocation | All |

| Gantt Chart | Juliette |

| System Diagrams & Structural Drafts | Benjamin |

| System Schematics & Structural Drawings | Benjamin, John |

| Budget Planning | Ramon |

| Research | |

| Target | Benjamin |

| Sustainability Research | Lauri |

| Ethics Research | Juliette, John |

| Marketing Plan | Benjamin, Ramon |

| Research on Materials | All |

| Design | Benjamin |

| Building & Testing | |

| Building Prototype | All |

| Environment | Lauri |

| Programming | John |

| Testing | All |

| Delivery | |

| Report | All |

| Presentation | Juliette |

| Leaflet | Lauri |

| List of Materials & Components | John |

| Paper | John |

| Poster | Lauri |

| Manual | Ramon |

| Website | Ramon |

| Wiki | All |

| Video | Ramon |

| Product | All |

1.8 Report Structure

This report followed a logical sequence, composed of eight chapters. Each of these chapters were divided into sections. The report was organized in such a way as to make the reasoning and explanations as clear as possible. The chapters were:

- Introduction: Presentation of the Team, of the reasoning and the motivation behind the choices, the main problems the Team faced, and some requirements for the project.

- State of the Art: Existing products, technological system and snail's life-cycle.

- Project Management: Overview of how the Team managed the project, the management tools such as a Gantt chart, cost and time diagrams.

- Marketing Plan: Description of the current market situation and presentation of the marketing strategy.

- Eco-efficiency Measures for Sustainability: Explanation of the choices to make the project as sustainable as possible.

- Ethical and Deontological Concerns : Description of the ethical concerns the Team had addressed.

- Project Development: All of the technological choices, tests and results.

- Conclusions: The conclusion the Team had garnered from the project, any alternative solutions that may work.

2. State of the Art

2.1 Introduction

To get started, an explanation of Escargot Nursery was introduced. This chapter also comprised the description and comparison of five existing products meant for home use, and four snail farm products which were already on the market, in order to draw conclusions and to take up relevant ideas that could be used in this product. This chapter contained information about the Cornu aspersum life-cycle and their optimal living conditions. In addition, there was an explanation of technologies used in “EscarGO” required for snail breeding.

2.2 Escargot Nursery

An Escargot Nursery was a product designed to grow snails, providing them with a comfortable living environment. The Nursery needed to be able to host a number of snails with ample space, along with soil coverage and other things they may needed to grow correctly (see Section 2.4 Escargot Research).

“EscarGO” was the commercial name chosen for the indoor snail farm the Team was developing during the EPS program (see Chapter 4. Marketing Plan)

2.3 Existing Products

2.3.1 Products for Home Use

There were some existing products similar to this project as shown in Table 2, meant for home use. These products were the competitors of the “EscarGO” project, since they were designed for domestic use. There was only one direct competitor also designed for snails. Due to the lack of products designed specially for snails, people were using products designed for other pets and because of this, the Team decided to study also some of those alternatives. Most of them were very basic without any technology. The “EscarGO” had to push the boundary and not to be only something technologically better and more advanced than what was already on the market, but also something that was aesthetically pleasing.

| Name | Product | Price (€) | Animals | Technology | Size (cm) | Other specifications |

|---|---|---|---|---|---|---|

| Grow your own escargots by S'cargo [5] |  | 46 | Snails | No technology | 30 x 30 x 30 | Bell shaped propagator and saucer as attractive snail farmhouse with sterile bedding. Instructions to help you keep the snails healthy and growing. Some special dry snail food to give them a good start. |

| Aqueon® Glass Aquarium [6] |  | 14 | Fish | No technology | 31 x 16 x 20 | Material: glass, features: no assembly required |

| Zoo Med™ ReptiHabitat® Bearded Dragon 40 Gallon Terrarium Kit [7] |  | 172 | Reptiles | A custom dual screen top provides easy access to the habitat and keeps your reptile safely inside. Including UV lighting. A dual temperature/humidity gauge to maintain temperature. | 91 x 45 x 45 | Lamp bedding, food samples |

| All Living Things® Hermit Crab Habitat Kit [8] |  | 30 | Crabs | No technology | 30 x 30 x 25 | Kit includes a soaking dish, seashell palm tree, sponge, sprayer, resin coconut hut and instruction manual. Cage is made from plastic and metal for durability |

| biOrb® FLOW 4 Gallon LED Aquarium [9] |  | 90 | Fish | biOrb 12V Transformer. biOrb Air Pump. Airstone. Standard LED light unit. | 21 x 30 x 31 | Ceramic Media 450 g. Filter cartridge. Water Conditioner 5 ml. Beneficial Bacteria liquid 5 ml. Material(s): Acrylic Aquarium |

The Team decided to choose a concept similar to the design of an aquarium, because the product needed to be simple yet attractive. The use of transparent sides would allow the users to see and enjoy the growth of their snails. In order to distinguish the product from the competitors, the Team decided to include several technological aspects in the design, like lighting, temperature and humidity control.

2.3.2 Snail Farm Products

There were already existing snail farms on the market, using different technologies to farm them. Since most of the home-use competitors of the “EscarGO” were not designed for snails, a comparison between bigger snail farming solutions was made. The Team considered this comparison relevant to the development of the product, due to the lack of techniques used in the products for domestic use. These technologies were dedicated to raise a much larger number of snails, whereas this project was designed for a much smaller number and for domestic use (see Table 3).

| Name | Picture | Size (m) | Description | Advantages/Disadvantages |

|---|---|---|---|---|

| Hutch Box [10] |  | Not given | This system was a square or a rectangular box. The floor was filled with sieved black soil to a depth of 18 - 25 cm. In addition, at the bottom of the box, there were holes in order to evacuate the excess water. The lid was in wood or steel frame lidded with chicken wire and nylon Mesh. This system was particularly adapted to semi-intensive breeding. | Advantage: easy to move, to feed the animals and to take care of them. Disadvantage: the cost of the system. |

| Trench Pens [11] |  | 0.6 × 0.6 to 1 × 1 | This system was directly inserted into the ground. In addition, the wall consisted of sandcrete blocks or mud bricks in either case. | Disadvantage: needed to kneel to take care of the animals. |

| Mini-Paddock Pens [12][13] |  | The walls should be 50 cm high and be dug at least 20 cm into the ground | This system was a small square, usually within a larger fenced area. Built of bamboo, nylon mesh, or timber, chicken wire and nylon mesh. | Advantage: sustainable system because of the materials. Disadvantage: the snails were less protected against predators than the previous systems. |

| Free Range Pens [14] |  | 10 × 20 | Large system. The vertical fence must be extended inwards, to prevent snails from escaping. | Advantage: mimics the natural environment of the snails so the life conditions were optimal. Disadvantage: it required a lot of space and it may be expensive. |

Unlike “EscarGO”, the systems above were for outdoors and not for indoor use. These, despite following a very different approach to a home product, they had some ideas the Team could look up to.

These did not include any control system on humidity or temperature. They were rather big and expensive and the ease of use seemed not to be one of their priorities. On the other hand, these systems were sustainable and recreated a natural place, and made a clever use of technologies like the curtain system.

The Team agreed on the need for an environmental control system included in the product, but also added the idea of using a nylon mesh to prevent snails from going into the heating system and applying the curtain system (see Subsection 2.5.1 The Curtain System). Additionally, a natural environment had to be recreated

To conclude, the purpose of these large-scale farming technology was only to raise snails for food production. The Team realized that the “EscarGO” had also some different purposes such as promoting sustainability (see Chapter 5. Eco-efficiency Measures for Sustainability), ethics (see Chapter 6. Ethical and Deontological Concerns) and family values, as well as having a much more attractive design.

2.4 Escargot Research

The Helix Pomatia was the most consumed snail. It was a wild snail that did not bear the promiscuity of intensive farming. Moreover, it took one year to grow. The Team decided to use the breed Cornu aspersum because this was one of the most common snail breeds and the most consumed snail in France. This breed was ready for consumption after six months [15].

2.4.1 Life cycle

The Cornu aspersum belongs to the class Gastropoda, they prefer an undisturbed habitat with adequate high moisture and good food supply. The snail is hermaphrodite so a single snail may have male and female reproductive organs. The age of sexual maturity is reached between its first and second year of life and the breeding season is at the beginning of summer. Prior to reproduction, the Cornu aspersum perform courtship behaviours before mating, like reciprocal tactile contact. Just before mating, the snails shoot structures called “love darts”, The use of love darts is a form of sexual selection. The whole mating process takes 4 to 12 hours [16].

After mating, both snails can deliver a set of eggs, which increases the chance of survival. When fertilization occurs, eggs develop. Laying eggs happens about 3-6 days after the copulation. The snails will produce around 80-86 spherical pearly white eggs into crevices in the topsoil or sheltered under stones. Before laying their eggs, the snails build a nest digging a hole in the soil, between vegetation or on the ground. The snail digs with the aid of its ventral foot until obtaining a hole with a depth of 2.5 to 4 cm. The size of the egg is around 4 mm. The Cornu aspersum breed can produce up to six batches of eggs in a single year, each new-born will take one to two years to mature depending on the weather and region [17] [18].

Under favourable conditions, eggs hatch after approximately two weeks. The shells of hatch-lings are fragile and translucent and snails emerge with a soft shell. They therefore need to feed themselves calcium by consuming the remains of their egg and even other eggs that have not yet hatched. Eggs are particularly sensitive to dehydration and cold temperatures. The baby snails have, in addition to a soft shell, an almost transparent body that acquires strength and colour as it grows. The first colour they usually have is bluish but then turns to brown. They grow remarkably fast, but very few reach one year of age. Shells continue to grow with the snail over the course of its life, and the rings it has are indicators of their age. A single snail can live 2 to 7 years [19] [20].

2.4.2 Living Conditions

Cornu aspersum are herbivores, a polyphagous grazer with a wide spectrum diet. It finds its food in fruit, trees, herbs, cereals, flowers and bark of trees but occasionally, they add to their diet organic matter in decomposition. The Cornu aspersum is very sensitive to temperature, light intensity and humidity

Feeding Requirements

The snails move through all of the terrarium, to get food. Snails tend to keep company when feeding, and are generally social creatures. Sometimes several snails feed together on one piece of food, even if there are other food sources available. The snails will prefer to eat plants rich in calcium and reject plants rich in metals like zinc and nickel. There are herbs and vegetables that snails almost always want to eat, like cucumber, but even these lose their attraction if they are not given a change in diet, just like any other creature, they tire of the same food source and need a varied diet. Other vegetables are only taken at certain times of the year. It is also possible to feed the snails with leaves from vegetables, like cabbage, turnip leaves or leaves from carrots and radishes. Kitchen waste from vegetables can be fed as well, for example aubergine peel, tomato slices and cucumber peel [21] [22].

Feeding activity is essentially nocturnal and occurs only when relative humidity is sufficient, around 80 %. The snails don’t eat at random, snails use distance chemoreception and taste to discover their choices, feeding preferences being influenced by the biochemical composition of the plants and especially by secondary metabolites [23].

Environment Requirements

Activity of the snails necessitates a temperature of between 15 and 25 °C and a humidity between 75 and 90 %. The optimal temperature is 21 °C, if the temperature comes below 7 °C, snails hibernate. If conditions are unfavourable, adult snails are able to remain asleep for a few months. They cannot withstand long periods of frost. Micro-habitats are variable, but the snails preferably choose habitats with greater light intensity and structural complexity. The Cornu aspersum lives in coastal dunes, grove and bush land, between rocks. The snail isn’t dependent on a limestone underground, it needs habitats with hiding places in rock and wall crevices or below a deep vegetation cover [24].

The soil is a major part of the habitat because good soil allow the snails to grow well. The snails dig into the soil to lay their eggs, so the soil should not contain too much sand or clay. The organic matter needs to be 20-40 % because this enhances cation exchange capacity of calcium which stimulates growth. In the soil, there needs to be adequate calcium, the primary content of their shells. A good option to introduce calcium is to add ground limestone at a suggested concentration of 4.5 kg per 100 square feet (9.3 m2). Snails need dampness. A soil moisture content of 80 % is recommended. In the hours of darkness, air humidity above 80 % will promote the activity and growth of the snails. The soil needs to be changed every three months [25] [26].

Climate

The Team focused on France, and in most parts of France there is a Cs climate, based on the Köppen climate system. A Cs climate means “Mediterranean climate” a warm temperature climate with dry winters. For the Cornu aspersum this is the preferred climate [27].

Light Requirements

Light is very important to the snails, the light influences their behaviour. To have an optimal reproduction and breeding process, this factor needs to be controlled. The Cornu aspersum needs 16 hours of light. A simple timing device can be set for the time lengths. A system that can be used is watertight fluorescent tubes, they have the capacity to deliver a 40 W power output and spaces at distances. It will acquire a diffusion of light within the reproductive environment [28] [29].

Space Requirements

Population density is also very important, too many snails affects the successful growth and breeding capacity of snails. Snails tend not to breed when packed too densely or when the slime accumulates too much. The slime suppresses the reproduction of the snails. The snails grow slower when they are in a densely populated area. Another disadvantage of high density is the high rates of parasitism and transmission of diseases. An advised density for Cornu aspersum is 1-1.5 kg per m2. An adult snail is around 10 grams, so it is possible to put 100 snails on one square meter [30] [31].

2.5 Escargot Nursery Structure Requirements

In order to host 50 snails in optimal conditions the Team had to provide the snails with enough (half of a square meter) space as stated above (see Subsectioon 2.4.2 Living Conditions - Space Requirements). To increase their living surface while keeping a product’s size that would fit its home use, the Team applied a curtain system (see the following section). It was also important to keep the volume inside the box as low as possible. That way the “EscarGO” required a sustainable amount of power to keep the humidity and temperature at the appropriate intervals.

The materials should also stand the test of time the way the competitor’s product did (see Section 2.3 Existing Products); Polypropylene (PP) plastic was the material the Team decided to use to achieve this.

2.5.1 The Curtain System

A new method for snail farming is the curtain system. The curtains hang in the box and the snails can climb up the curtains. With the curtains, it is easier to keep more snails, because of the larger surface area for the snails to live on [32].

The use of the curtains has many more advantages, the feces of the snails falls down. This method has no impact on the life cycle of the Cornu aspersum. They do not need to be placed in horizontal position, they can also move, mate and sleep in vertical position. It is also easier to make daily inspections because the user has visible contact with the snails without touching them [33].

The curtains can be made of nylon. This is a textile and is easy to clean.

2.6 Advantages and Disadvantages of the Escargot Nursery

Based on the state of the art study, the Team realised some of the product’s Advantages compared to the existing technologies. As per the “space requirements” section, it was possible to put 100 snails on one square meter. This was why the Team had chosen the dimensions 400 mm x 300 mm x 375 mm with a curtain system, so the project takes up less space. With the curtain system that had been chosen there could be a larger concentration of snails in a smaller area.

Another advantage of the “EscarGO” was the inclusion of the environmental control system, that provided a comfortable ambient environment, with little input from the end user. The Team decided the systems of heating and cooling needed to be automatic, so the users did not need to interact with the system much, and did not need to be home at all times such as they do with other pets.

Product’s design was also an advantage compared to other similar products. The product was designed to be sat in a home, such as in a living room or kitchen, so the product needed to be attractive enough that it would blend well with other pieces of furniture.

On the other hand, compared with existing technologies, the “EscarGO” seemed to have some disadvantages. Despite it being useful for the breeding of snails, the addition of an environmental control system to the product made it needed a power source, while the competitors did not need any.

The cleaning of the “EscarGO” would be slightly more difficult than the other products as a result of the inclusion of the curtain system. Despite being easier to clean, the curtains may needed to be cleaned more often than other parts of the snail enclosure.

2.7 Conclusion

To conclude, this state of the art proved that the product must have dimensions of 400 mm x 300 mm x 375 mm in order to breed 50 snails.

Moreover, the study showed that this particular breed of snails is sensitive to humidity, temperature and light. Thus, the Team has decided to add an environmental control system, including light, humidity and temperature control to the “EscarGO” so the user did not need to pay attention to the snails that often because they felt the need to make the product more user-friendly.

Based on the snail farm products, the Team decided to adopt the curtain system to increase the usability of the product because the surface area will be larger. The use of nylon is useful to separate the snails from the heating system.

3. Project Management

3.1 Introduction

According to its definition, a project is above all unique. So, there was no pre-established organisation for its realisation. Thus, project management was the set of tools, techniques and methods that enable the project manager and his or her Team to lead, coordinate and harmonize the various tasks carried out within the framework of the project. The aim of project management was to respect all the relative imperatives related to the projects like time, delays, costs, quality risks. In order to make the project successful, the Team had run the following project management study, including:

- Scope

- Time

- Cost

- Quality

- People

- Communication

- Risk

- Procurement

- Stakeholders Management

3.2 Scope

The Work Breakdown Structure (WBS) was an important part of Project Management. The Team had recorded all tasks and divided them into categories. By doing this, the Team could made the WBS as shown in Figure 2.

3.3 Time

Gantt Chart and Deliverables

The Team established the planning of the project using a Gantt chart (see Figure 3).

In Table 4 a summary of all the deliverables and deadlines of the project is displayed.

| Deliverable | Deadline |

|---|---|

| Gantt Chart | 2017-03-06 |

| “Blackbox” System Diagrams & Structural Drafts | 2017-03-13 |

| System Schematics & Structural Drawings | 2017-03-27 |

| List of Materials (What & Quantity) | 2017-04-03 |

| Upload Interim Report & Presentation | 2017-04-09 |

| Complete List of Materials (local providers & price) | 2017-04-24 |

| Interim Presentation | 2017-04-20 |

| Upload Refined Interim Report | 2017-05-02 |

| Upload Functional Tests' Results | 2017-06-05 |

| Upload Final Report, Presentation, Video, Paper, Poster and Manual | 2017-06-18 |

| Final Presentation, Individual Discussion and Assessment | 2017-06-22 |

| Hand in a CD with the Corrected Deliverables | 2017-06-26 |

| Hand in the Prototype and User Manual to the Client | 2017-06-29 |

| Receive the EPS@ISEP Certificate | 2017-06-29 |

3.4 Cost

When managing the project, it was essential to monitor the costs to remain within budget. The costs relating to a project were the costs of the materials used and also the costs of the labour or the workforce (see Figure 4).

Cost management could be done through a pre-established process:

- First, the plan for cost management needed to be produced. This meant that all the internal procedures must be established so the budget could be assigned in the correct areas.

- Next a cost estimation needed to be done to evaluate the costs of materials.

- Then the budget can be determined.

- During the project, the Team needed to manage costs. This step consisted of updating project costs and managing changes affecting the base cost reference.

As the budget had been set by ISEP, which was 100.00 € to build the prototype, the principal requirement in regarding to the costs during this project was to manage the costs and stay within the budget.

The material resources for building the prototype are showed in Table 5

| Product | Quantity | Cost (€) |

|---|---|---|

| 16×2 I2C LCD Display | 1 | 8.50 |

| Fan 12V PC Fan | 1 | - |

| Arduino Uno | 1 | - |

| Luminosity Sensor Breakout - TSL2561 | 1 | 6.50 |

| DHT22 | 1 | 9.80 |

| Resistors | 4 | 0.20 |

| NPN Transistor | 2 | 0.98 |

| Solenoid 12 V | 1 | 9.40 |

| Capacitors | 4 | 0.60 |

| LED Strip | 3 | 8.88 |

| Wiring | 2 | 0.50 |

| Arduino Power Supply AC/DC 230 VAC/12 V 2 A | 1 | 7.50 |

| ULN2003 Stepper Motor Driver Board | 1 | - |

| PVC Sheets | 2 sheets of 100 cm x 50 cm | 21.58 |

| Polymethylmethacrylate (PMMA) | 0.137 m2 | - |

| Plastico autocolante black and white | 4 | 5.72 |

| Clear plastic tube | 1.5 meters | - |

| Nylon Mesh | 1 | - |

| UHU Allplast | 1 | 4.00 |

| Shipping costs | - | 8.22 |

| Total | 95.53 |

Thus, the total costs of the materials was 95.53 €.

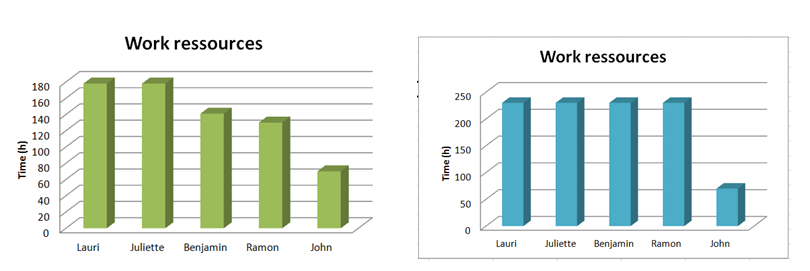

The work resources for building the prototype shown figure 4

3.5 Quality

According to standard ISO 8402-1986 quality is “the totality of features and characteristics of a product or service that bears its ability to satisfy stated or implied needs”. The quality of a product is a pillar of the success of any business. If the product is of good quality, consumers will be more inclined to buy products from the company again, i.e. Brand Loyalty, but also if people experience a high-quality product and service they are more likely to recommend the product to their friends and family, which has the added bonus of being free advertisement. Quality is the key indicator of the success of the project, but it’s also an obligation since companies must comply with a certain number of standards in terms of quality such as ISO 9000 and ISO 9001. With such high importance being put on quality, most big companies have a department dedicated to quality management [34].

Quality management is a process that started at the very beginning of a product's design. When designing a product, the product designers and engineers made sure that the materials that are used are fit for purpose, for example a hairdryer could not be made from plastic that can melt easily. Using quality management techniques such as acceptance sampling, engineers could determine if the materials that were used within the product were of satisfactory standards. If a company is using a particular brand of bolts, they will test 3 % of the batch, depending on batch size, and if the bolts are not accepted then the bolts will be sent back to the supplier [35].

In the “EscarGO” project the materials were purchased from reputable sources, and non-destructive tests were conducted before use of the prototype. Solidworks software was used to build 3D models, and also for the electronics. By using open source software, the design of the electronics were carried out and simulations were undertaken before the electronic components were built and assembled.

Testing the prototype was an important part of the quality, the Team wanted to deliver a product of quality. Figure 5 shows that all the parts that needed to be tested, sensor of humidity, temperature and light were be tested one by one. This was important because when a test failed, the Team knew instantly what the reason was. After testing the parts one by one, the whole prototype was tested.

Quality needed to be ensured for the duration of the life of the product, by providing after sales service in case of any problems and a warranty. The after sales service was also a measure of the success of the “EscarGO” society because if customer problems were solved quickly, they would be more satisfied.

3.6 People

Human resource management or people management was an important part of project planning. It included the activities and processes, in which each team member was involved. The tasks were assigned to an individual, but each person assisted the others with input in team meetings. The tasks were assigned on a skills basis. The Team consisted of so many differing backgrounds and specialisms which brings something unique to the Team (see the following section).

3.6.1 RAM

The group used a Responsibility Assignment Matrix (RAM) (see Table 6) as an essential part of their project planning.

| Task | Benjamin | John | Juliette | Lauri | Ramon | Supervisors |

|---|---|---|---|---|---|---|

| Gantt Chart | A | R | A, C | |||

| BlackBox | A | R | A, C | |||

| Structural Drafts | R | A | A, C | |||

| State of the Art | R | R | R | R | A, C | |

| Eco-effiency Measures for Sustainability | R | R | R | A | A, C | |

| Ethical and Deontological Concerns | A | R | R | A, C | ||

| System Schematics | A | R | A, C | |||

| Structural Drawings | R | A | A, C | |||

| Cardboard Model | R | R | R | R | R | A, C |

| Marketing Plan | R | A | R | A, C | ||

| Project Management | A | R | R | A, C | ||

| List of Materials | R | A | I | A, C | ||

| Interim Report | R | R | R | R | A, C | |

| Interim Presentation | R | A | R | R | R | A, C |

| Building | R | R | A | R | A, C | |

| Programming | A | R | I | T | A, C | |

| Testing | R | T | T | T | T | A, C |

| Website | A | I | R | A, C | ||

| Video | R | A | R | A, C | ||

| Leaflet | R | A | R | R | A, C | |

| Paper | R | R | A | A, C | ||

| Poster | A | R | R | A, C | ||

| Manual | I | A | R | A, C | ||

| Final Report | R | R | R | R | R | A, C |

| Final Presentation | R | R | R | R | R | A, C |

- R: Responsible

- A: Approval

- C: Consultant

- I: Informant

- T: Tester

3.7 Communication

In order to achieve the best possible project, it was essential to ensure good communication within the group. Since everyone came from different countries, with different languages there may be problems with comprehension. Thus, it was very important to be clear, rigorous and to repeat the explanations if necessary.

Moreover, as everybody came from different specialties, all having differing knowledge bases, that was why it was very important to communicate in order to develop ideas, and consider perspectives from fresh eyes. In addition, communication was essential in order to resolve any problems that may arise within the group. To work in good conditions, it was important that there was a good atmosphere without underlying problems.

There were many means of online communication that could be used to improve communication when the Team was not together at school.

First of all, when the Team wanted to organise meetings, ask their colleges for help or divide the tasks, the Team could use the Messenger application in Facebook. Messenger was very useful when several people wanted to work on the wiki because, it was not possible to work at the same time as the work would be lost. The Team also used both Dropbox and Google Drive so everyone could upload their work to a shared online platform and furthermore, different people could work at the same time on the same document on Google Docs. This was also good for a backup safeguard. The fact that everyone had access to everything, allowed the whole Team to have a view on the whole project. So, everyone could express their opinion on the work accomplished.

The Figure 6 represents the distribution of the various means of communication mentioned above. Oral communication represents half the diagram because the Team spent a lot of time in school working together. Google Drive was used more than Dropbox because it allowed the Team to write in a shared document, several at the same time and that was more convenient. The Team also used a lot of Messenger because it allowed them to talk in real time even if they were not together. At the beginning WhatsApp was used but since it was not practical for everyone, it was abandoned as a means of communication.

Table 7 shows the communication matrix.

| What | Why | Who | When | To whom |

|---|---|---|---|---|

| Deliverables | To develop the project | The Team | On the date of the deadline | The supervisors and the Team |

| Weekly supervisor meetings | To discuss about the progress of the project | The Team | Every Thursday | The supervisors |

| Agenda | To inform supervisors about the topics of the meeting | Team member who was responsible for the agenda that week | Before every Thursday | The supervisors |

| Brainstorming sessions | To discuss about the different ideas, project planning | The Team | Multiple times a week | Other team members |

3.8 Risk

Risk management was an ongoing process that identifies the risks involved with each task and provided a solution to mitigate risks to the health and safety of the individual or group that were involved in the task. In this project, to avoid risk, the Team decided to identify and analyse all the potential risks that may arise and think about possible solutions.

Risk management included the following six processes:

- Establish objective

- Identify risks

- Assess impacts

- Assess risks

- Risk control

- Monitoring

Table 8 shows the risk management.

| Risk | Cause | Effect | Trigger | Response | Impact | Probability | Rank |

|---|---|---|---|---|---|---|---|

| Broken components | Poor quality of the components | It will be not possible to build a fully working prototype of the product | Prototype testing failure | Quality check of components on arrival (mitigate) | High | Medium-low | 4 |

| Not meeting the interim deadlines | Bad planning | Lower grade | Teachers and coordinators bad input | Good planning. Weekly tasks. Communication (avoid) | Medium-low | Low | 8 |

| Illness of the team members | Bacteria, virus or a work accident | Slowing down the work rate and quality | Team member feels sick | Follow a healthy lifestyle (accept and transfer) | Medium | Low | 6 |

| Faulty components delivered | Components broken because of bad protection while transporting | Cannot build the prototype before the deadline | Material delivery check | Check for shop's reviews before buying (avoid) | High | Low | 5 |

| Tests fail | Bad or wrong components | A non-working prototype | Prototype testing | Test all the components one by one, before testing the entire prototype (accept and mitigate) | High | Medium-low | 3 |

| Inappropriate material selection | Bad materials research | Impossible to construct the designed model | Prototype resting | Ask teachers and supervisors for advice (mitigate and transfer) | High | Medium | 2 |

| Conflict with stakeholders | Bad communication | Slowing down the development of the project | Communication with the stakeholders | Implement communication plan and measure and meet stakeholders expectations (avoid) | Medium | Low | 7 |

| Electronic problems | Insufficient knowledge about electronics | Product will not work | Electronic schematic is not finished | Ask for help (accept) | High | High | 1 |

3.9 Procurement

Procurement was the process of acquiring and buying products, goods or services from external suppliers. The process was used to make sure that the Team received products at the best possible price but also high quality compared with other external suppliers, i.e. the best value.

For this project, the Team was only allowed to choose suppliers from Portugal, which meant that there were more restrictions on what could be used in the final product. In some countries, the components that were needed to build the prototype, were cheaper, better quality than in Portugal and in some cases, could not be found with Portuguese suppliers. This produced a design challenge and made the Team think harder about the materials that were contained in the design solution.

3.10 Stakeholders Management

Stakeholder management was an important part to make the project successful. The stakeholder was a person that had influence over the Team or was influenced by the Team, whether that be an investor in the business, or someone who's livelihood is tied up in the business. A part of the stakeholders management could be, making sure that the Team was meeting the deadlines, making a product of good quality and that the product was going to make money.

In this project, there were different stakeholders with different expectations. The stakeholders in this project were the supervisors, the Team members and the university. Table 9 shows the stakeholders.

| Who | Role | Expectations | Power | Influence |

|---|---|---|---|---|

| The Team | The Team develop the project | Learn new skills and develop a working product | High | High |

| Supervisors | Supervise the project | Receive an interesting project and a working product | High | High |

| Teachers | Give information about different subjects | Gain knowledge that is necessary and receive an interesting project | Low | Medium |

| Suppliers | Provide materials | Sell the materials | Low | Low |

| Consumers | Buy the product | Receive a good working product | Low | Medium |

| ISEP | Sponsor | Receive interesting projects | High | Low |

The graph in Figure 7 gave another view of the influence of the stakeholders.

3.11 Conclusion

To conclude this chapter, project management was one of the main aspects of the realisation of the project. Project management was a useful and important tool for the team members to identify all the tasks and time limits, to guide the cost and the budget, to measure the risks and to analyse the responsibilities of the people that were involved.

The main objective was to organise the project planning in an efficient manner. The project planning ensured each team member was clear of their responsibilities, identified the time limit and the tasks that needed to be done. The Team made a Gantt Chart with all the time limits and tasks highlighted for each team member. With using the Gantt Chart, the Team was up to date with all the tasks and time limits.

In the next chapter the marketing aspect of “EscarGO” is introduced.

4. Marketing Plan

4.1 Introduction

Marketing was the set of actions undertaken to encourage people to buy a product or service. In this chapter, an explanation about the market situation analysis, potential customers, segmentation and target market, strategies, product, price and promotion was also discussed. The analysis started from a macro level, going closer to the own business. All levels had an impact on the activities and decision making of the company. Taking into consideration this data, the Team provided a suitable marketing plan for the product, explaining the necessary actions to achieve the marketing objectives covering the first year of the product launch.

4.2 Market Analysis

4.2.1 Macro Environment

The first step of the market analysis was a Macro Environment Analysis where the Team tried to define possible opportunities and threats within the industry. These factors were external and uncontrollable by the Team, they affected the performance and decision-making. The macro environment could be divided using the Political, Environmental, Social, Technological, Legal and Economic (PESTLE) model (see Figure 8).

Political/Legal

The political/legal factor defined to what extent politicians, the government and legal directives had an influence within the industry. In the case of the Escargot Nursery, many governments supported the idea of home production of food [37]. Also, food education is a big topic, as big budgets are spent for healthy students. The Escargot Nursery could be used at home, but also for educational purposes in school.

Since this product used living animals and these may be used for cooking at home, care needed to be taken about norms related to living creatures as well as nutrition and health laws. In order to release the “EscarGO”, the Team had to comply with E.U. legislation related to selling consumer goods in Europe (see DIRECTIVE 1999/44/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 25 May 1999) and product safety (see DIRECTIVE 2001/95/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 3 December 2001), but also food contact materials regulation (see Food Contact Materials - Regulation (EC) 1935/2004 ).

Environmental

The carbon footprint of the food was reduced in different kinds of ways. First of all, it eliminated the food transportation from the other side of the world to the dinner table. Moreover, molluscs and insects were used instead of meat as protein source, because meat production spills enormous amounts of fresh water and energy. Special attention was needed when choosing materials for the product. Instead of using production techniques for assembly of a product with a linear life cycle (production to landfill), circular life cycle should be considered.

Social

The social environment analysis defines cultural, demo-graphical and behavioural trends, values and norms. Social media was becoming increasingly important in our culture [38]. That was why the project needed to incorporate social media when it came to marketing but also improve the real-life contact between the users. It had to connect the different members of the family in order to improve social cohesion. Other social trends like going back to the basics, growing your own food and food education work in favour of the home Escargot Nursery.

Technological

Technological trends focused on the change in use of technology. Automation of some processes like temperature and humidity control made maintenance much easier. Internet Of Things (IOT) was already used in a lot of products and its use was only expanding. Therefore, it would be a possibility to implement it in the Escargot Nursery future development as it also improved social connection. Technology was needed to improve and optimize the life cycle of the snails (heating/humidity/light).

Economic

Economic factors described elements of the economy that had an effect on the industry and the company itself. These factors could be the price of energy, inflation, income etc. Escargot were expensive as food and with the Escargot Nursery customers could produce the snails themselves for home use or for (small) commercial interests.

4.2.2 Micro Environment

The micro environment was external factors not controlled by the Team, which directly affected the decision-making and performance the Team had to undertake. These elements were: customers, suppliers, intermediaries, public and competitors.

Customers

The consumers were the intended target group for which the Escargot Nursery was designed. The needs of the customers had to identified, implied, satisfied an anticipated. It was important not only to sell the product, but also realise a long-lasting customer relationship.

There are two different customers:

- The home user: the home user wanted a product to grow snails for the purpose of consumption. Snails were a delicacy and were therefore not cheap.

- The educational user: the educational user focused more on the development of the snails than on using them for food.

Suppliers

Suppliers provided the necessary resources that enables the company to make its products or services. The Escargot Nursery contained many electronic parts, such as sensors, user interface, controller, heating and cooling device. There was also the material needed to build the casing and the interior of the terrarium. All of these components were bought in Portugal. To get the best parts and materials at the lowest prices, extensive research was needed.

Intermediaries

Intermediaries stand between the customers and the company. They are the middlemen who promote, distribute and sell the product to the users. The Escargot Nursery would be sold Business to Business (B2B) and mainly as Business to Consumer (B2C) as well. Because the nursery was a relatively new product, potential customers would not know of its existence. The B2B market gave the company a wide reach and product visibility. In addition to the B2B market, the company could sell directly from the website. These days, internet selling is a standard practice and done by almost all companies.

Public

The public was a broader and more general term than targeted customer, but they also had actual or potential interests in the product. While designing, making and selling the Escargot Nursery the Team had to take into account some groups beside the intended consumer. One of these groups were the animal protection groups like People for the Ethical Treatment of Animals (PETA). The product had to be of decent quality, and provide the snails with a very comfortable habitat so consumer protection groups would not protest. Another group to take in account was the media. They had great power to make or to break the sales of the product.

Competitors

Competitors also influence the actions made by the company, because they offered similar products or services. There was a difference between direct and indirect competitors.

The one and only direct competitor was the GROW YOUR OWN ESCARGOTS by S’cargo (see Subsection 2.3.1 Products for Home Use). S’cargo was a company owned by Helen and Rachel Howard who were artisan food producers. The product had a bell-shaped propagator and saucer. Additionally, there was a detailed care instruction to help keeping the snails healthy and growing. Before the consumer could start, he had to send a card to receive the escargots and dry food at home. The price was 35 £ Sterling and the dimensions are approximately 29 cm x 28 cm x 29 cm.

The advantages of this product were the low price and small dimensions. There was no technology included in the product which makes it easy to use and consumed no energy.

Disadvantages were the high number of attention needed to grow the snails. The dimensions were small, so only a small amount of snails could be kept inside. Temperature and humidity was not controlled so the snails could die without the right care. Carbon monoxide poisoning was also a problem as the whole structure is sealed

Indirect competitors made product that were similar to the snail farm, but were meant for other purposes. Some snail enthusiast kept their pets in aquariums or terrariums. For these product, there was a much bigger market. They existed in every price class and with different amount of technology. Professional snail farms made their own snail huts. Usually they were made from wood and/or nets and the focus was on food production, not usability, aesthetics or education. But these professional snail farms needed a lot of care and attention.

4.3 SWOT Analysis

This Strength, Weaknesses, Opportunities, and Threats (SWOT) analysis was used to warn the Team about the dangers that developing this product may have had, and also to help the Team make the most of their possibilities. These four factors must be divided into external (opportunities and threats) and internal (strengths and weaknesses). Internal factors were those the Team could control, while the ones that were outwith the Team's control are the external factors, most likely consumers and competitors (see Figure 9).

The project had some weaknesses. First of all, before the start of the project, none of the team members knew anything about snails and their breeding which was an obstacle to overcome. In addition, none of the “EscarGO” Team really have had any serious business experience and since the product did not have direct competitors, they could not study their marketing strategies. The Team had a small advertising potential because, at the time, snails were not known to the general public as pets. Many people found snails disgusting and the idea of raising snails was really odd for them. The team members came from different countries and did not speak the same first language, which could represent a weakness to communicate with one another and made their points of view clear, but the Team saw this as a benefit, as it brought a wide range of knowledge, and meant that the sources that could be used for research could be in many different languages. Everyone communicated in English, which the Team spoke to differing levels.

This product also had many strengths. It was an original product because it did not exist on the market. So, the idea was very innovative and would prove to be a curiosity for potential customers.

As one of their main objectives was to make the product as sustainable as possible, the product did not require a lot of power since it was intended for indoor use, reducing the need to change the atmospheric conditions of the inside of the “EscarGO”

The Team needed to take advantage of the opportunity to be a leader in the market. “Caracol” had no competitors, and that could be an opportunity to develop the product and start a new and wide market. This was a project where team members came from different degree programs in their home Universities, they could acquire knowledge from the others and improve their own skill set. Moreover, it was an opportunity to learn how to lead a Team, and simulate a project in a professional environment.

Despite the opportunities, the project also had threats. The Team had a budget of 100.00 €. “Caracol” had to make choices in order to remain under the budget. Additionally, the Team had a tight schedule which they found to be difficult to manage the time. There was also the issue where the workshop was only open at certain times and could only be used for 3 hours at a time. To conclude, other potential threats were that a lot of people do not want to eat the snails they have bred. For instance, most people who raise rabbits, or any edible animals, found the idea of eating them inconceivable as they were pets.

4.4 Strategic Objectives

In Table 10, in order to achieve the long-term success of the “EscarGO” product, the Team stated the Specific, Measurable, Achievable, Realistic, Timed (SMART) objectives that were used as a reference to measure the past, present and future of the company in a realistic approach (see Figure 10 ).

| Objective | Description | Time |

|---|---|---|

| Final product | Build the final fully-functional “EscarGO”. | August 2017 |

| Launch development | Obtain funding. Reduce production costs. Start the publicity campaign. | September-November 2017 |

| Product launch | Sell the product through the company’s website in the Christmas campaign. Sell at least 20 units. | Christmas 2017 |

| First year | Find a distributor/supplier. Increase the production and sell more than 150 units during the year. | 2018 |

| Expansion | Promote and sell the product in other European countries, like Spain. | 2019 |

4.5 Segmentation

The Team divided the market into smaller segments to be reached more efficiently and effectively. This study helped the Team to be aware of the market segmentation and areas that are more likely to be interested in “EscarGO”.

4.5.1 Geographic Segmentation

In the Geographical Segmentation study, the Team decided which countries would be their target markets. The “EscarGO” product would mainly be sold as an educational and recreational product, but it would also be advertised as a way to grow your own snails at home for consumption, to reach other target markets. For this reason, the Team did research on which countries consume the most snails, in order to find those countries where the cultural barriers related to snails would be less important [39].

Snail meat is healthy and nutritious, and is relatively high in proteins, and in addition there is high amount of omega-3. It is also a source of minerals (mostly Ca, P, K, Mg, and Na) [40], but due to cultural issues it was not consumed globally.

It was estimated that over 400 000 t of snails were consumed every year around the world [41] (it is thought that a higher number was actually consumed due to a large proportion of snails that had been hand-picked from nature) [42].

Only 15 % (67 500 t) of the global consumption came from snail breeding units while the largest amounts of snails traded in the market came from nature (85 %) [43] [44].

The largest consumer markets were located in Europe. Three countries had the highest escargot demand. These were France, Italy, Spain. The difference between France and the other two was notable though (see Figure 11).

In France, they usually consumed more than 40 000 t of snails a year [45] [46] [47]. Italy ranked second in the list of EU snail meat consumer after France. Italians consumed 37 000 t of snails meat during 2010 [48]. Their usual consumption was around 33 000 t a year [49]. Spanish, in third place, consumed 16 000 tons of snails a year [50].

What held true for the three of them is that all these three countries were heavily in deficit (see Figure 12). Specifically, in France more than 80 % of domestic consumption was covered by imports. In Italy about the 65 % whereas in Spain the 55 % [51].

In France, in 2010 there was a shortfall of 90 000 t snails due to their high consumption that year. Based on this information, it was expected that this need for snails would not be covered even in the next 10 years [52].

The highest consumption of snails per person had been recorded in Greece; about 40 000 t in 2015 [54], though their average total consumption every year is usually lower. There, according to the Presidential Act 67/81 (FEK 43/A/ 1981) collecting snails from nature is permitted only from March until June [55].

Based on these statistics ,the Team decided to focus the market mainly in France for their first active year. Later on, the Team would consider expanding their business to other countries like Italy, Greece or Spain.

All of these countries had a mild climate without extreme conditions allowing the growth of snails, since the Cornu aspersum is natural from this climate (see Section 2.4 Escargot Research). For this reason, the climate control of the product would not require a non-sustainable amount of power to achieve the optimal living conditions.

4.5.2 Demographic Segmentation

The product’s size was meant for home use, so the marketing strategy tried to approach families living in the big cities of France, for instance Paris, Marseille, Lyon, Toulouse or Niece (see Figure 13).

Additionally, the “Caracol” Team decided to focus on the population segment with the following characteristics :

- Age:30 to 35 years old

- Family size: in a couple / married - preferably with children. For educational target purposes

- Income: medium to high

- Type of accommodation & situation: flat in a busy French city center, far away from nature

- Professional situation: working

The Team decided to advertise the “EscarGO”mainly as an educational product and chose to aim for an age range of between 30 and 35, based on statistics (see Figure 14) that showed it was the age when people in France seemed to be starting a family [57]

At the time of publication, France had a total population of 66 990 826 people. The age sector of 30 to 35 years old population comprised a total of people 4 947 116 (7.38 %) [58]. This demographic sector of the french population seemed not to be growing or decreasing at the time of the study (see Figure 15).

4.5.3 Psychographic Segmentation

The Team, based on the statistics introduced in Geographic Segmentation and Demographic Segmentation chapters, decided to focus on median income working class families who live in a busy environment filled with distractions and technology. Parents craving additional quality time with their children, worried about their education, since they were easily exposed to many different kinds of media coming from TV and Internet. The product the Team decided to make, provided a solution that allowed the user to not have that much interaction with the snails as other pets did (fish, etc.), by the use of automatic humidity and temperature control systems and also because of the high resilience of snails as animals. For these reasons, the group thought this product would be attractive to families living in a busy environment, that may not have that much free time to spend on a pet.

If children asked to have a pet, the “EscarGO” would require less work and time than a dog for example. The “EscarGO” would require much less work, only requiring one cleaning every three months. The rest of the time the only interaction that the snails require is feeding.

4.5.4 Behavioural Segmentation

This product aimed to attract modern families who live in a busy environment filled with distractions and technology. The Team also noticed that escargot was a common Christmas dish in France. Two thirds of the French escargot production per year were consumed during the Christmas period [60]. The imports seemed to peak just before the end of the year as a result of this traditional festive dish [61] (see Figure 16).

Customers would only buy this product once. For that reason, loyalty was not as important as user satisfaction and customer reviews were. The aim was to get parents recommending this product to their friends with children, while the children would talk with their friends from school about the fun product they owned.

4.5.5 Levels of Market Segmentation

There were four different levels of marketing segmentation:

- Mass Marketing: same product to all consumers

- Segment Marketing: different products to one or more consumers

- Niche Marketing: different products to one or more segments

- Micromarketing: products suit the tastes of individuals and locations

The Team decided to aim their Mass Marketing strategies towards French people aged 30 to 35 years old. The group applied a Niche Marketing strategy, to advertise the product mainly as an educational and recreational product for families, but also as a gastronomical experience for couples or single people wanting to grow their snails for consumption at home. In the future development of the company, “Caracol” would also advertise themselves for B2B companies that may be interested in the product, like schools and pet shops (education/recreational) or small restaurants or food shops (gastronomy).

4.6 Strategy/Positioning

A clear position in the market provided the company a competitive advantage over other similar products. The positioning strategy allowed the company to differentiate themselves from competitors. It provided an image for the customer and is based on the segmentation section. Besides meeting the needs of the end user, it was also important to find a gap in the existing market.

To determine the company's position in the market, certain tasks had to be undertaken:

- Identifying Possible Competitive Advantages.

- Choosing the Right Competitive Advantage.

- Communicating and Delivering the Chosen Position.

The existing market consisted of one direct competitor (S'cargo) and a lot of indirect ones (see Section 2.3 Existing Products). If the Escargot Nursery was to be different from its competitors the following requirements had to be achieved. The Escargot Nursery focused on ease of use, made possible by sensors and electronics. It was the only technological product specific for raising snails. “EscarGO” could be used to keep snails as pets, as well as food production. The real distinction of the product was the social aspect that the product met. The Escargot Nursery brought families together and taught kids about nature and food production.

The perceptual map (see Figure 17) shows the connection between need for maintenance and the number of snails the nursery could contain. These two values were important to find a gap in the existing market. All direct and indirect competitors were in the fourth quadrant, which was the one with high maintenance and low number of snails. The quadrant with low number of snails and low amount of maintenance, for example the small led lighted aquarium, had to be avoided because of the size. The professional nursery with high number of snails and high maintenance was not useful for the chosen target market. The only existing competitor in the upper left quadrant were well equipped terrariums for reptiles. The terrarium didn't have to be very large, but big enough for feeding a normal size family for two meals a year.

4.7 Adapted Marketing-Mix

The Team used the marketing mix to adjust their position in the market by taking into consideration the product price, promotion and place (see Figure 18)

4.7.1 Product

The Team decided to use the commercial name “Caracol” for the brand (see Figure 19). The name of the product would be “EscarGO” (see Figure 20). The logos for these commercial brands were designed to be appealing to families and kids.

The product did not have many competitors. Most snail nurseries were not designed to be used as a domestic product. The dimensions of the “EscarGO” had to fit in a normal house or flat. It was also necessary to make the product easy to use so that children could also use it. Since loyalty was not important for a product people would only buy once, the Team wanted to have their clients recommending their product to others.

To comply with legal requirements that all consumer goods sold in the EU had, (see DIRECTIVE 1999/44/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 25 May 1999), the group included a two-year warranty with the product.

4.7.2 Price

To decide the product’s final price, the Team had only one direct competitor to compare it with. “GROW YOUR OWN ESCARGOTS” by S’cargo cost 46.00 € (see Section 2.3 Existing Products). It was only sold online and it did not have any built-in technology. The “EscarGO” could be sold at a higher price since it was a much higher quality product, but the Team had to be careful not to over price the product that it would lead customers to decide to go with the competitors.

It was also a must to take into account the product’s production costs and group’s profit. The Team had a budget of 100.00 € to develop the prototype. Once built and after the tests would be performed, “Caracol” would have to keep the actual production costs of the products around 40.00 to 50.00 €, in order to sell the product on a reasonable profit. Considering these factors, the Team aimed to sell the product at 50.00 to 70.00 € price depending on the economies of scale.

The payment methods their internet site would accept would be PayPal, credit card, and Cash On Delivery (COD), in order to make the sale as easy as possible for the customers. The Team did not plan to add any discounts when buying more units, since this product would not sell large quantities of units to a single buyer. The delivery taxes when sending this product to the metropolitan France would be included in the final price.

4.7.3 Promotion

The Team was very aware of the importance of promotion and advertisement of “EscarGO”. There were a large number of different options available to promote the product, and the right or wrong choices the Team made would determine the success or failure of the product’s launch.

For the Team’s site to reach the target market, the “Caracol” group applied a digital marketing strategy.

It included a careful Search Engine Optimisation (SEO), which consisted on choosing the title of the site, an appropriate description and keywords like “escargot” “pet” or “home” so that the website was accessed through the search providers more effectively.

Another feature of the “EscarGO” site was a Frequently Asked Questions (FAQ) section, along with an explanation video. In the future, the Team would also add a chat option for help. All of these actions were taken to make a more personal approach to selling the product.

The last feature of the Team’s digital marketing strategy was internet advertisement. It allowed the Team to have a full control of the message when promoting the “EscarGO”. The Team decided that pay-per-click Google Ads suited the advertisement of the product in the best way. The website was also optimised for smartphone view, to allow the visitors to enter the site throughout smartphone advertising.

The Team would also consider applying a public relationship strategy that would include giving away the product or the product's poster and leaflet to schools in France for free. The main objective would be the children testing the product at class, while the teachers would test the product as a teaching tool as well.

4.7.4 Place

In this section, the focus was on the marketing and distribution channels for the “EscarGO”.

Thanks to the lack of competitors at the time, the Team decided to sell the product using internet selling and distribution through their website: (https://caracoleps.wixsite.com/escargo) (see Figure 21) The “Caracol” portal is optimised for both desktop and smartphone view. It would include a customer reviews section once the product was launched.

The Team took the decision to sell directly to the consumer through online selling as a main distribution channel. They also considered other marketing channels like specialized pet stores, or supermarkets. These would only be located in crowded cities in France, since there was no need for this kind of product in the countryside. The group decided it was too early for the product to be sold using those channels. The product should be more known before those channels could be used.

4.8 Budget

A budget of 5000.00 € was set aside by the company as marketing budget. This amount of money was used to increase the brand awareness among the French consumers. That way, the Team expected to increase their sales. It included the elements used to get the product ready to be launched to the market and customer communication related actions (see Table 11).

| Action | Budget (€) |

|---|---|

| Leaflet | 600.00 |

| Flyer | 600.00 |

| Website | 1200.00 |

| Google Ads | 1000.00 |

| Social Media | 1600.00 |

| Total | 5000.00 |

4.9 Strategy Control

Strategy control was about the current state and the state in the immediate future of the company. Rather than thinking about past decisions, strategy control controlled the execution of the strategic plans. This control enabled the company to improve and optimize the ongoing processes, but also feedback the ongoing plan to the original plan. The assumptions made by the company in the beginning of the development process about trends, customers and the environment were refuted or confirmed. In order to do this, after the launch of “EscarGO” consumers had to be questioned. This would give the company the right data for the strategic control.

4.10 Target Market Survey

The Team used google forms to make a survey and ask potential customers about their interest in this kind of product and how would they wanted it to be like. The survey was translated into English, French, Spanish and Portuguese. It received 165 responses (see Figure 22) which helped the Team to make some decisions about the development of their product.